BOXER - Air Operated Diaphragm Pumps

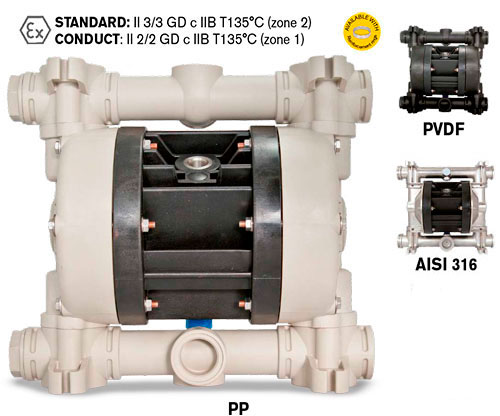

BOXER 7 Pneumatic Pump

up to 9 l/min

1/4”

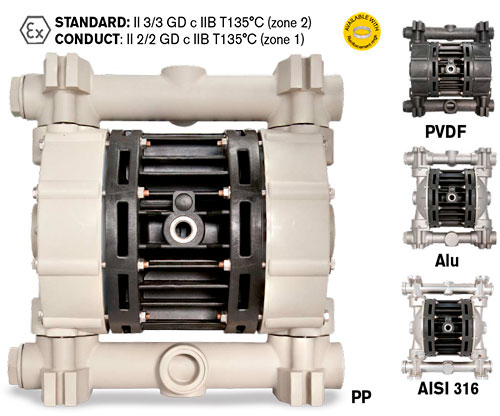

BOXER 15 Diaphragm Pump

up to 17 l/min

3/8”

Pump BOXER FPC 100 PTFE

up to 130 l/min

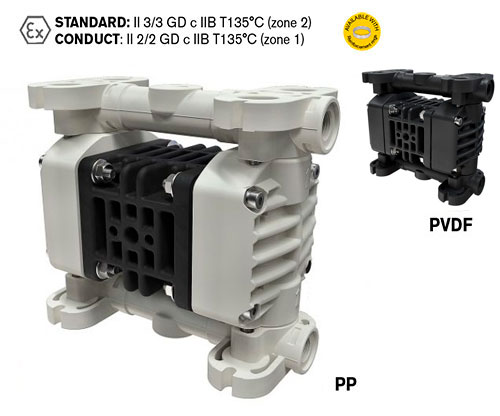

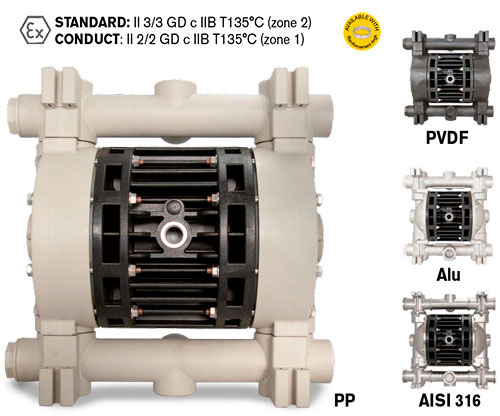

MICROBOXER Diaphragm Pump

up to 30 l/min

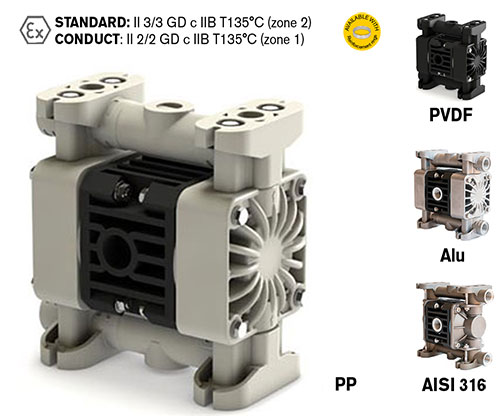

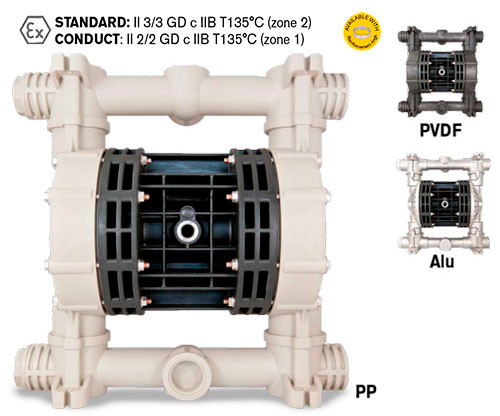

MINIBOXER Pneumatic Diaphragm Pump

up to 60 l/min

BOXER 50 Diaphragm Pump

up to 60 l/min

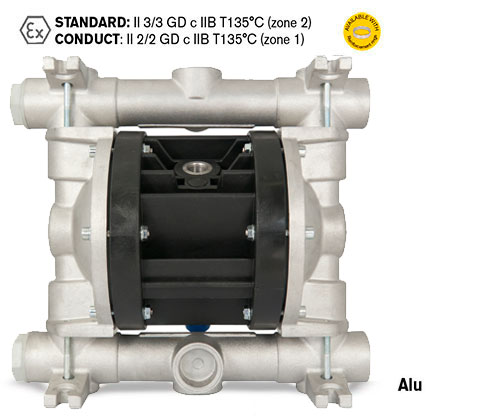

Aluminium diaphragm pump BOXER 90 BOXER 90

до 100 л/мин

1" или DN 25

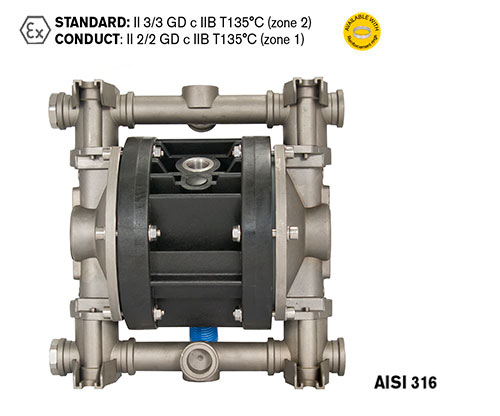

BOXER 81 Diaphragm Pneumatic Pump

up to 100 l/min

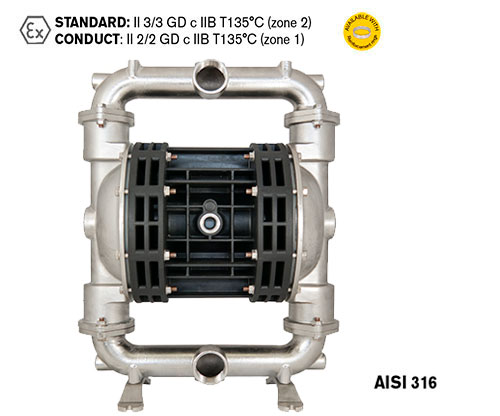

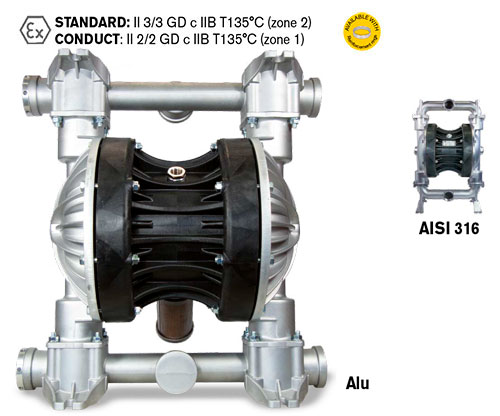

BOXER 100 Pneumatic Diaphragm Pump

up to 150 l/min

BOXER 150 Diaphragm Pump

up to 220 l/min

BOXER 251 Volumetric Diaphragm Pump

up to 340 l/min

Double diaphragm pump BOXER 252

up to 340 l/min

BOXER 522 Pneumatic Diaphragm Pump

up to 650 l/min

BOXER 502 Metal High Performance Diaphragm Pump

up to 650 l/min

BOXER 503 Pneumatic Diaphragm Pumps

up to 900 l/min

BOXER DIAPHRAGM PUMPS FOR VISCOUS MEDIA

Among the features of BOXER diaphragm pumps one can define exceptional capacity, power and strength, which makes them ideal for pumping liquids with very high viscosity up to 50000 cPs (at 20°C), even if these liquids contain suspended solids.

Diaphragm pumps are characterized by dry self-priming capacity with considerable suction head, even if the pump is not full, fine tuning of speed without pressure loss, adjustable flow and head, and the possibility of continuous operation without overload and damage. In addition, a huge choice of construction materials allows selecting optimum chemical compatibility with the fluid and/or the environment without neglecting the temperature range.

They are specifically designed for applications in high humidity or potentially explosive environments (ATEX certification).

Diaphragm pumps with pneumatic drive are designed for pumping abrasive, shear sensitive and viscous liquids. In addition, they excellently cope with heavy and flowing liquids.

Advantages of BOXER diaphragm pumps

Pneumatic diaphragm (diaphragm) pumps have the following advantages

Mobility. The equipment is lightweight, which makes it easy to carry without additional attachments. Ease of installation. To connect the pumps, it is enough to connect the suction and pressure hoses, screw in the compressed air connection and click on the air hose.

Security. The equipment is started by simply opening the air supply valve. The only parameter that must be monitored in this case is the pressure - it should not exceed the maximum allowable values set by the pump manufacturer. The ability to work "dry". Lack of liquid in the suction line is not a problem for diaphragm pumps.

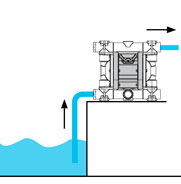

Self-priming. Due to the creation of a deep vacuum, the equipment is capable of lifting liquid from a height of up to 5 meters or more with an empty inlet line. Wide range of pumped liquids. A wide range of components made of various materials will ensure chemical compatibility even with very aggressive substances. Capable of pumping viscous and dense liquids, as well as media with solids, without the threat of damage to the pump.

High abrasion resistance. Membrane equipment is well suited for the ceramic industry. Explosion-proof. These pumps do not generate sparks during operation and do not heat up above the permissible temperature. In the presence of a conductive housing, they can be used in rooms explosive with gas or dust.

Possibility to adjust performance and pressure. Relatively low price. Diaphragm pumps, in comparison with other equipment for solving similar problems, can often be bought at a more attractive price.

Ease of maintenance. No high qualification of personnel or special knowledge is required to replace components. It is enough to have the usual tools and repair instructions.

Hygienic and pharmaceutical grade possible

MAIN FEATURES:

- Designed and made in Italy

- Self-priming capability

- Not afraid of dry running

- ATEX certification for ZONE 1 - ZONE 2 IECEx certification

- Adjustable performance

- Suitable for viscous fluids and demanding tasks

- Possibility of pumping liquids with suspended solids

- Suspended installation

- Clamp-on attachments and DIN 11851 available (only pumps in AISI 316)

- LONG LIFE diaphragms (available in various elastomers) for greater strength and durability

- Suitable for continuous service

APPLICATION:

- Water treatment. Pumping test dosing of acids and alkalis for pH-control. Pumping flocculants, suspended solids, chemicals and sediments. Pumps are resistant to hydrochloric acid, ferric chloride, and to many other aggressive substances.

- Paint and varnish industry, and typography. Pumping paints based on solvents and water, inks, varnishes, adhesives, binding substances and solvents. In addition, such pumps can be also applied to pumping, spillbacking and mixing inks in printing.

- Sanitary use. Pumping food products, such as soups, milk, yogurt, alcohol, dough, pasta and toothpaste. Service applications, such as spraying cleaning fluid in CIP (cleaning system).

- Mechanical engineering. Pumping oil, grease, lubricants, coolants, liquids for washing and cleaning solvents and waste of production.

- Paper industry. Pumping adhesive, sodium silicate, paints, titanium oxide, etc. Bleaching process, sampling and pumping sewage.

- Chemical industry. Pumping all types of acids, alkalis, alcohols, solvents, products thaat are susceptible to coagulation, such as latex and emulsions, as well as chemical waste water.

- Surface treatment. Pumping chemicals out of swimming pools, bathtubs and containers, for example, while etching, electroplating, degreasing, etc, as well as pumping wastewater.

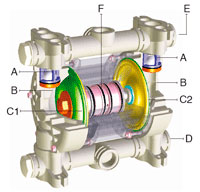

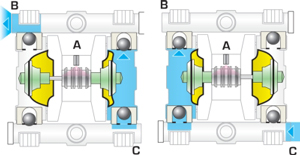

The Way It Works

The compressed air generates from the pneumatic exchanger (А) through one of the two diaphragms. It compresses and pushes the product into the outlet manifold (В). The fluid is intaken as a result of decreased pressure created by the opposing diaphragm (С) that is integrated with pneumatic exchanger. After each stroke, the pneumatic exchanger diverts the compressed air to the opposing diaphragm, and the cycle is reversed.<

Max. Viscosities

| Pump Model |

Max. Viscosities Expressed in CPS |

Percentage of Flowrate decrease with Max.Viscosities |

| Microboxer | 20000 | 80% |

| Miniboxer/B50 | 20000 | 85% |

| Boxer 80/81 | 25000 | 90% |

| Boxer 100 | 30000 | 85% |

| Boxer 150 | 35000-40000 | 90% |

| Boxer 250/251 | 45000-50000 | 90% |

| Boxer 502/503 | 45000-50000 | 90% |