FOODBOXER - Food-Processing Diaphragm Pumps FDA

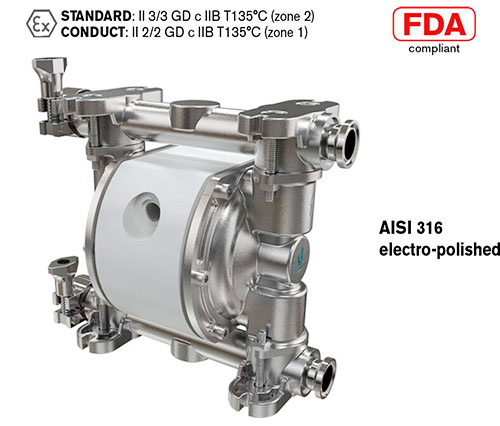

FOODBOXER 30 Diaphragm Food Pump

up to 30 l/min

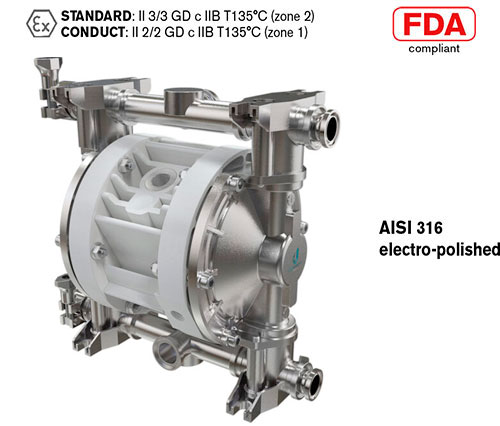

FOODBOXER 50 Diaphragm Food Pump

up to 50 l/min

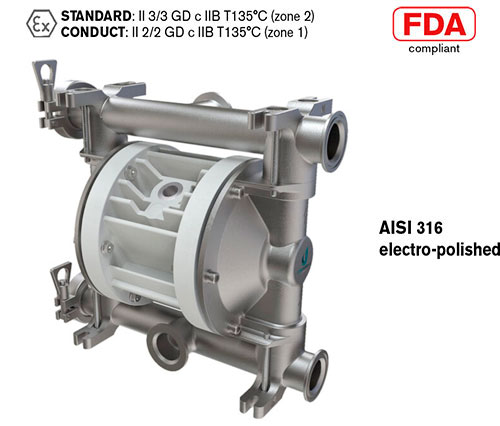

FOODBOXER 80 Pumps Membrane Food

up to 100 l/min

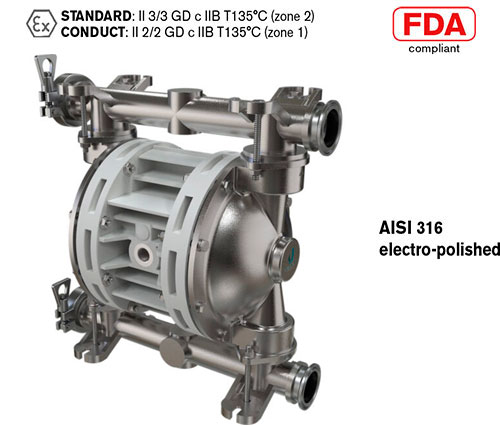

FOODBOXER 100 Diaphragm Food Pump

up to 150 l/min

FOODBOXER 150 Hygienic Food Pump

up to 220 l/min

FOODBOXER 251 Diaphragm Pump

up to 340 l/min

FOODBOXER 502 High-performance Food Pump

up to 650 l/min

FOODBOXER 503 Food Pneumatic Pump

up to 900 l/min

FOODBOXER FOOD-PROCESSING AND SANITARY PUMPS FOR FOOD AND PHARMACEUTICAL INDUSTRIES

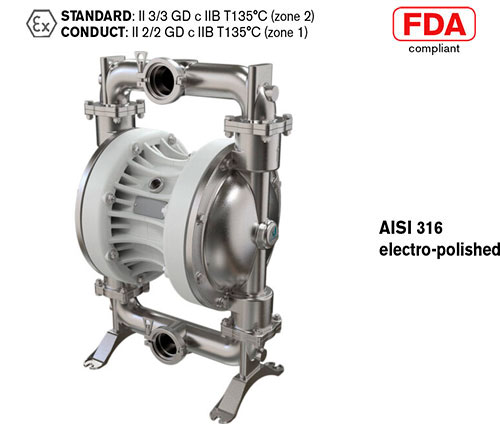

FOODBOXER food hygienic pumps are designed for use in such industries as: food, brewing, pharmaceutical, cosmetic; All materials used in the manufacture of these pumps are FDA (Food and Drug Administration) compliant. The pumps are manufactured from AISI 316 stainless steel, electropolished to an average roughness of just 2.7 µm.

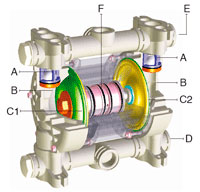

Foodboxer hygienic food pumps are self-priming even at a considerable suction lift, when the pump is not overloaded, it is also possible to fine-tune the speed without loss of pressure, adjust the flow rate and pressure, and the possibility of long-term operation without overload and damage.

A wide choice of materials for component parts allows for full chemical compatibility with the liquid and / or the environment, taking into account the required temperature. Their design allows them to be used in such harsh environments as high humidity and explosive environments (ATEX certification).

FOOD-PROCESSING SANITARY PUMPS| MAIN FEATURES:

- available in PP (polypropylene), PVDF (polyvinylidenfluoride)/ECTFE (ethylenechlortrifluoroethylene), ALU (aluminum) and AISI 316 (stainless steel);

- used in potentially-explosive environments (ATEX certification);

- suitable for severe conditions and high-humidity environments;

- dry operation is allowed;

- dry start up;

- the drive is the energy of compressed air without using any particles of lubricant;

- adjustable performance and operating suction head

- fine tuning of motor speed at constant pressure;

- double-manifold option (two inlet and two outlet openings);

- ground, wall or submersible installation;

- three inlet and three outlet manifolds;

- easy maintenance and parts replacement;

- excellent performance, price/quality ratio;