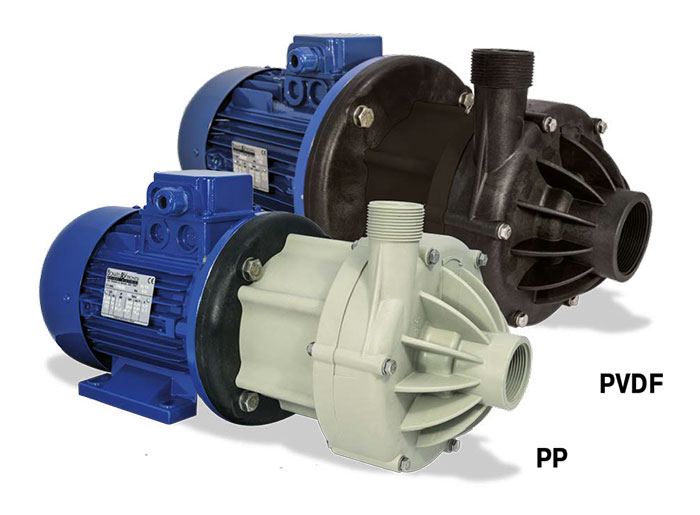

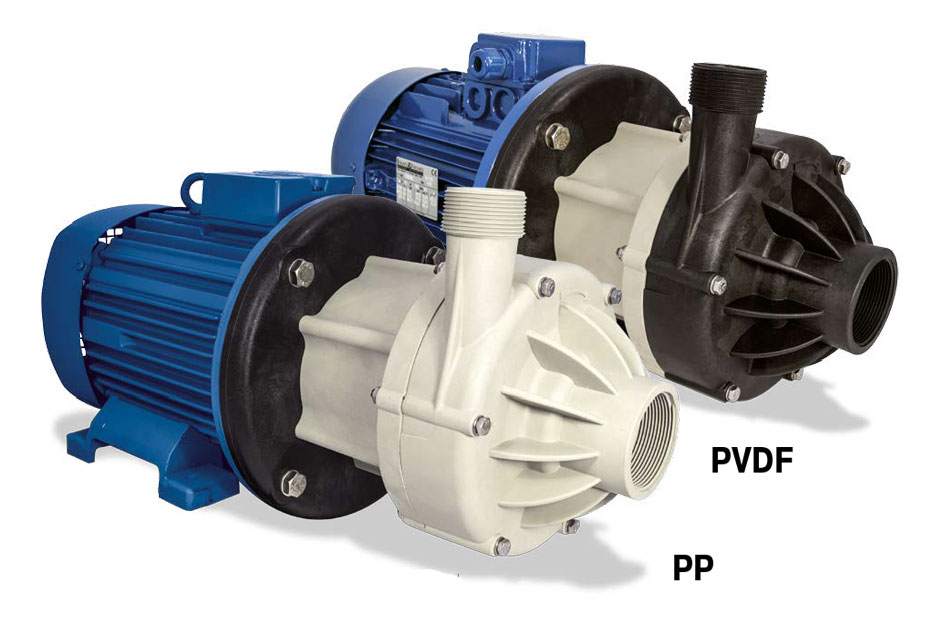

DM - Magnetic Drive Centrifugal Pumps

DM 06 Magnetic Drive Pump

up to 6 m³/hour

DM 10 Magnetic Drive Centrifugal Pump

up to 13 m³/hour

DM 15 Magnetic Drive Centrifugal Pumps

up to 23.5 m³/hour

DM 30 Magnetic Drive Chemical Pump

up to 35 m³/hour

Magnetic Drive Centrifugal Pumps DM

DM magnetic drive centrifugal pumps are the ideal solution for many industrial applications. The complete absence of metal parts in contact with liquids makes them especially ideal for pumping acids and aggressive products.

The pumps operate using a pair of magnets, an external magnet located on the motor shaft transfers movement to an internal magnet integral with a closed impeller. The impeller of the pump (closed impeller) is not physically connected to the motor shaft, therefore the gaskets are excluded and, as a result, leaks of the pumped liquid caused by wear.

Some of the main applications are in laboratory or medical equipment, photographic development machines, in the electroplating, chemical industries, water treatment plants, aquariums, filtration plants, heat exchangers, silver recovery systems, the graphics industry, and X-ray processes. Magnetic drive centrifugal pumps are made up of few components, making maintenance extremely easy

- The pumps are available in polypropylene (PP) or polyvinylidene fluoride (PVDF).

- The equipment is designed and made in Italy;

- Use under the bay;

- Extreme ease of maintenance; Suitable for continuous work.

Example of pump marking: DM 06P - SD1BE071

- DM 06 - pump size.

- P - polypropylene body (FC - PVDF fluoroplastic, glass fiber reinforced).

- S - support bearing made of a combined material (ceramic + Teflon).

- D - EPDM O-rings (V - Viton).

- 1 - standard impeller (2 impeller size reduction, 3 - even more size reduction).

- B - BSP thread (corresponds to GOST 6357-81 thread).

- E - coupling for MEC engine flange (European standard).

- 071 is the standard for engine height.

Type of installation of a pump with a magnetic coupling DM