News and Last Events

AODD pumps for the food and beverage industry

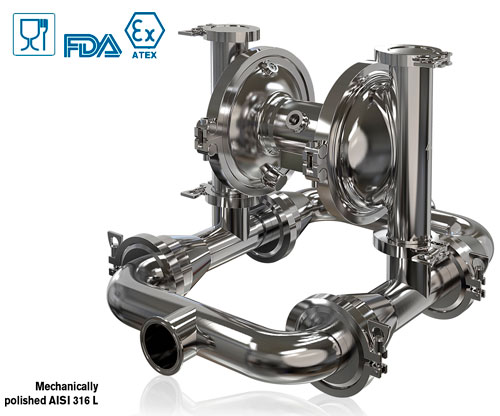

Pneumatic Double Diaphragm Pumps (AODD Pumps)

Double diaphragm pneumatic pumps (AODD pumps) represent an excellent solution for pumping and transferring a large variety of fluids in different application sectors. The main advantages deriving from the use of AODD pumps concern the high application versatility, the minimum maintenance requirements, the ability to ensure cleaning operations without complexity and an excellent cost-effectiveness ratio.

Thanks to their innovative features, Debem diaphragm pumps represent an excellent solution also for the food and beverage market, ensuring use in line with the hygienic standards of excellence required by the sector. This aspect is fundamental for a sector in which safety and quality are the main elements to be evaluated at the level of planning the production process and minimizing risks.

Designed to gently handle a wide variety of processes within the food and beverage market, Debem pneumatic double diaphragm pumps can improve production efficiency, reliability and safety of any industry application.

Food industry requirements for selecting a diaphragm pump

The food processing industry processes a very complex and varied range of raw materials. The production factors that fall within the food production processes are often expensive and require highly controlled pumping and handling phases. Furthermore, the components of the product can have a particularly high viscosity or fluids characterized by the presence of solid particles. To these factors we add the requirement to comply with sector regulations which makes the selection of the right equipment imperative.

The hygiene factor is the number one concern for food producers. However, like all operating sectors, food companies must remain profitable. In addition to cleaning, companies also focus on minimizing product waste and maximizing energy efficiency.

The pumps used in the food sector must therefore be able to:

- Handle different types of liquids, from low to high viscosity.

- Accurately perform the functions of loading, unloading and transferring fluids.

- Handle a wide range of temperatures.

- Ensure hygiene and protection from environmental contamination that could compromise the entire production process.

- Manage routine cleaning and sanitizing operations.

Due to their intrinsic characteristics, double diaphragm pneumatic pumps represent the best solution to manage all food processing needs while keeping energy costs low.

Certified pumps: 3A – MOCA – ATEX – FDA

Advantages of Debem's AODD pumps for the food and beverage industry

The high versatility of Debem AODD pumps guarantees high application variability and the consequent possibility of being able to manage a wide range of viscosities, pressures and flow rates. For these reasons, Debem pumps are also an excellent choice for the food and beverage market.

First, Debem pumps, thanks to particular ball valves with an eccentric design, can manage the presence of large solid elements without causing damage to the pump structure. Unlike other pumping technologies, AODD pumps are self-priming and do not require positive inlet pressure to prime. They are also able to run dry: it is very common for pumps to dry out, especially at the end of a transfer from one tank to another.

All Debem pumps are equipped with a patented pneumatic exchanger capable of maximizing productivity with reduced air consumption. The materials used make transfer processes safe by optimizing fluid handling flows.

Debem pumps are simple to disassemble and clean. The quick emptying system ensures easy removal of the fluid from the product chambers to allow all washing and sanitizing operations without the presence of internal impurities. In terms of safety, Debem pumps can be equipped with special fiber optic sensors capable of alerting the operator and stopping the work of the pump in case of damage to the membranes and leaks of fluids.

A final important consideration concerns the economic factor: in most cases AODD pumps are characterized by a better quality / price ratio than other types of pumps such as gear pumps.

Conclusion

Debem SRL designs and manufactures double diaphragm pneumatic pumps suitable for use in the food and beverage industry. The AODD pumps produced by Debem SRL for these sectors are in AISI316 / AISI316 L Mechanically – polished. DEBEM sales engineers can support you in choosing the best solution in terms of configuration, size and materials. Contact the DEBEM team now for more information.